Sumitomo Heavy Industries (SHI) first entered the injection moulding machine business in 1965 and has been developing technologies that lead the industry. Their machines are known for innovation, precision, and reliability, especially in production environments that demand high cycle performance and reduced defects.

Standard model realizing sustainable molding

Mold clamping force: 300kN – 1800kN

Improved high speed, high responsiveness, and molding

Significantly enhanced the high-speed injection performance and highly responsive acceleration/deceleration performance

Mold clamping force: 500kN – 1800kN

Specializes in small-sized precision

Electric small-sized injection molding machine with an advanced direct drive mechanism, which features high horsepower and high responsiveness

Mold clamping force: 170kN

Additional mold mounting performance and excellent injection performance

Successor of SE-HDZ that realized even greater mold mounting performance

Mold clamping force: 2200kN – 5000kN

High cycle machine with excellent cost performance

SE-EV-S-HD-based special design molding machine with the high cycle equipment for containers

Mold clamping force: 2200kN – 5000kN

Achieves thinner goods and production cost reduction with the super precision high-speed molding

High-speed type electric molding machine equipped with the second generation direct drive mechanism

Mold clamping force: 2150kN – 3430kN

Improved high speed, high responsiveness, and high-load molding

Significantly enhanced the high-speed injection performance and highly responsive acceleration/deceleration performance

Mold clamping force: 2200kN – 4500kN

Realized speedy composite molding with compact size

Speedy production of two-material molding products that expand the applications as in high functioning and composite molding

Mold clamping force: 730kN – 1270kN

Composite molding realized in middle size

Electric middle-sized double-shot machine that speedily produces two-material molding products

Mold clamping force: 2250kN – 2740kN

Enhanced added value of product

All-electric two-material machine equipped with wide platen and high speed rotary table.

Mold clamping force: 4000kN

Leads the next generation lens molding

New special purpose machine for lenses with more than sufficient performance for optical lens molding, which continues to advance

Mold clamping force: 300kN – 500kN

Further precision in high cycle molding of small goods

Special purpose machine for connectors with more than sufficient performance for high cycle molding of small goods, which continues to advance

Mold clamping force: 300kN

Cleaner environment with electric machines

Providing unequaled quality and reliability with injection blow and mold technology

Mold clamping force: 1300kN

Further energy conservation

Electric PET pre-form molding machine developed for mass production of beverage

Mold clamping force: 5000kN

Zero-molding is an integration application that achieves as close to zero defects, losses, and faults as possible.

This application consists of three elements, including MCM (mold clamping-related technology), FFC (filling-related technology), and the system SPS that easily operate these technologies.

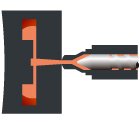

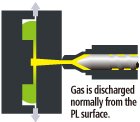

Reduce the maintenance work to utilize the vent effect and extend the mold life

Vent is clogged by excessive mold clamping force. It can result in short shots and gas burns.

Gas is properly discharged from the PL sides. It resolves short shots and controls mold deposits.

Low pressure and smooth filling promote venting, improving the cavity balance

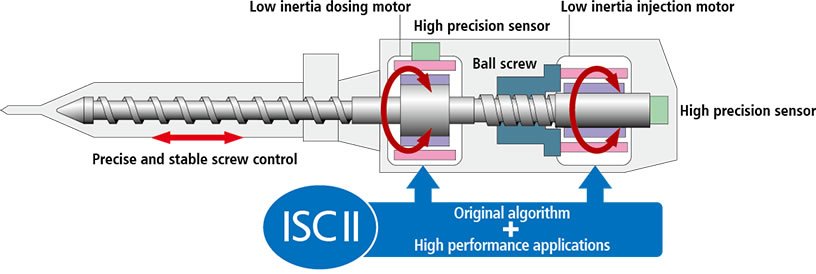

Screw control is highly responsive thanks to a structurally original injection system and low inertia servo motor.

Moreover, plasticization, filling and pressure holding are precisely and stably controlled by an in-house developed algorithm, which helps to lower injection pressure and improve cavity balance.

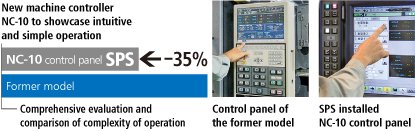

Error-free simple settings reduce preparation/operation time

40, Feeta Road, Trolla Parking Road, Backside of Devilal Park, Mullahera, Gurugram, Haryana, 122017

Plot no. G- 95, Phase- III, At Post Kuruli MIDC, Tal:, Chakan, Khed, Maharashtra 410501