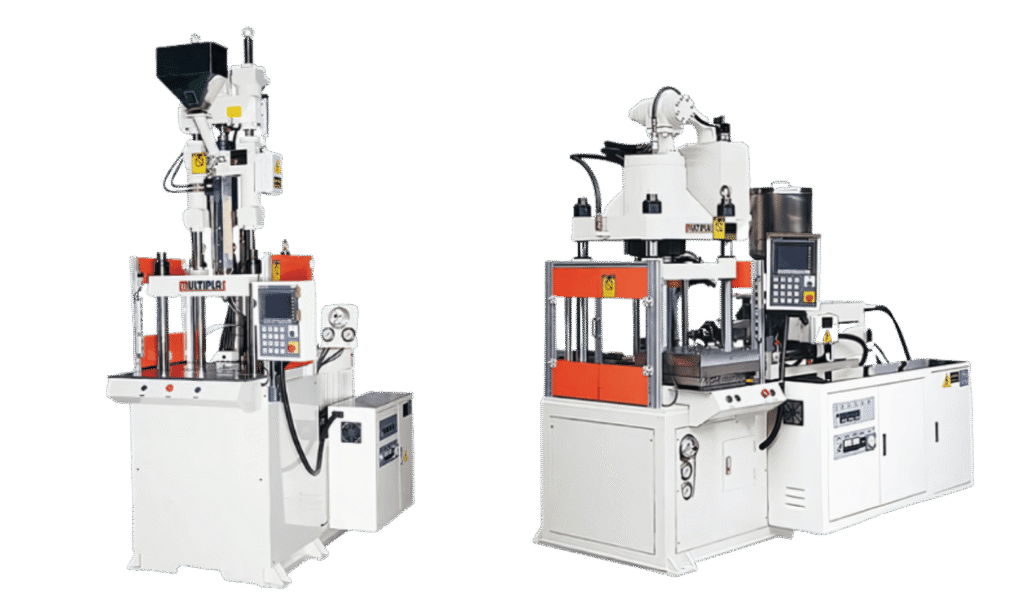

Multiplas vertical injection molding machines come in various configurations, aiming to meet diverse industry needs. Designed with precision, efficiency, and versatility in mind, these machines are engineered to revolutionize your production processes.

Clamping Force: 10 – 500 ton

Injection Capacity: 0.5 – 50 oz0

Main Features:

Vertical clamping, vertical injection.

Compact design requires less floor space. Makes the take-out process more easilier.

Suitable for multi-purpose injection molding. Excellent for insert molding.

Optional Feature : High-speed injection unit utilizing closed-loop system.

Clamping Force: 10 – 500 ton

Injection Capacity: 0.5 – 50 oz

Main Features:

Vertical clamping, vertical injection.

Compact design requires less floor space. Makes the take-out process more easilier.

Suitable for multi-purpose injection molding. Excellent for insert molding.

Optional Feature : High-speed injection unit utilizing closed-loop system.

Clamping Force : 10 – 500 ton

Injection Capacity : 0.5 – 50 oz

Main Features :

Vertical clamping, vertical injection.

Compact design requires less floor space. Makes the take-out process more easilier.

Suitable for multi-purpose injection molding. Excellent for insert molding.

Optional Feature : High-speed injection unit utilizing closed-loop system.

Clamping Force: 10 – 500 ton

Injection Capacity: 0.5 – 50 oz

Main Features:

Vertical clamping, vertical injection.

Compact design requires less floor space. Makes the take-out process more easilier.

Suitable for multi-purpose injection molding. Excellent for insert molding.

Optional Feature: High-speed injection unit utilizing closed-loop system.

Clamping Force: 35 – 200 ton

Injection Capacity: 1 – 20 oz

Main Features:

Vertical Clamping.

Tie-barless C-frame design facilitates insertion and take-out process.

Clamping Force: 35 – 200 ton

Injection Capacity: 1 – 20 oz

Main Features:

Vertical Clamping.

Tie-barless C-frame design facilitates insertion and take-out process.

Clamping Force: 35 – 200 ton

Injection Capacity: 1 – 20 oz

Main Features:

Vertical Clamping.

Tie-barless C-frame design facilitates insertion and take-out process.

Clamping Force: 35 – 3200 ton

Injection Capacity: 1 – 500 oz

Main Features:

Vertical Clamping.

Wider distance between tie bars. Strong structure to resist deformation. Clamping force up to 3200 ton.

The position of injection unit is freely adjustable. Makes the tooling design more easilier.

Diversified hydranulic system (Semi-closed Loop, Injection Closed Loop or High Speed Injection with Accumulator) is designed to meet different application needs.

Clamping Force: 35 – 3200 ton

Injection Capacity: 1 – 500 oz

Main Features:

Vertical Clamping.

Wider distance between tie bars. Strong structure to resist deformation. Clamping force up to 3200 ton.

The position of injection unit is freely adjustable. Makes the tooling design more easilier.

Diversified hydranulic system (Semi-closed Loop, Injection Closed Loop or High Speed Injection with Accumulator) is designed to meet different application needs.

Clamping Force: 35 – 3200 ton

Injection Capacity: 1 – 500 oz

Main Features:

Vertical Clamping.

Wider distance between tie bars. Strong structure to resist deformation. Clamping force up to 3200 ton.

The position of injection unit is freely adjustable. Makes the tooling design more easilier.

Diversified hydranulic system (Semi-closed Loop, Injection Closed Loop or High Speed Injection with Accumulator) is designed to meet different application needs.

Clamping Force: 35 – 3200 ton

Injection Capacity: 1 – 500 oz

Main Features:

Vertical Clamping.

Wider distance between tie bars. Strong structure to resist deformation. Clamping force up to 3200 ton.

The position of injection unit is freely adjustable. Makes the tooling design more easilier.

Diversified hydranulic system (Semi-closed Loop, Injection Closed Loop or High Speed Injection with Accumulator) is designed to meet different application needs.

No oil pollution and low noise, particulary suitable for clean-room production.

Full electric system reduces energy consumption by 40~70%, and yet ensures fast speed, high precision, and excellent stability of operations.

Unique toggie mechanism evenly distributes clamping force over the mould surface.

Solid and low-inertial structure designed for high-speed injection particularly suitable for precision moulding.

40, Feeta Road, Trolla Parking Road, Backside of Devilal Park, Mullahera, Gurugram, Haryana, 122017

Plot no. G- 95, Phase- III, At Post Kuruli MIDC, Tal:, Chakan, Khed, Maharashtra 410501